Boutique sports-car manufacturer celebrated for its minimalist, driver-focused machines. Established in 1991, Ariel’s flagship model, the Atom, eschews conventional bodywork in favor of an exposed space-frame and lightweight suspension, delivering razor-sharp handling and blistering acceleration. Every chassis and mechanical sub-assembly is designed, engineered, and hand-assembled at Ariel’s Somerset factory, with an emphasis on mechanical purity and track performance.

Beyond the Atom, Ariel has diversified into limited-run supercar projects (such as the Nomad off-road buggy) and recently introduced the high-power AAR concept based on automotive engine packages. Their R&D team continually tests new materials (including carbon composites and high-strength alloys) and collaborates with racing outfits to refine aerodynamic elements.

The global electronics industry is facing mounting pressure to reduce its environmental impact as electronic waste accumulates at record levels. According to the UN’s Global E-waste Monitor, a record 62 million tonnes of e-waste were generated in 2022 (an 82% increase since 2010). However, less than a quarter of that was properly collected for recycling, leaving US$62 billion in valuable materials unaccounted for. E-waste contains toxic substances (like mercury) and poses serious health and environmental hazards.

Regulatory bodies are also raising the bar for electronics manufacturers. A 2022 amendment to the Basel Convention now requires prior informed consent for all cross-border shipments of e-waste, hazardous or not, starting January 2025. Many countries enforce "extended producer responsibility" rules, meaning manufacturers must finance the collection and proper recycling of end-of-life devices. For example, the European Union’s WEEE Directive obliges producers to meet ambitious collection and recovery targets. These policies are prompting companies to design products that are more durable and easier to disassemble for recycling.

Consumers and advocacy groups are applying pressure as well. Increasingly, buyers factor environmental impact into purchasing decisions and demand longer-lasting, repairable devices. As one industry analyst notes, "consumers are becoming increasingly aware and concerned about their environmental impact, so sustainability amongst smartphone OEMs will become more and more important." High-profile campaigns (such as Right-to-Repair) and annual e-waste awareness events have further amplified demand for greener electronics. This shift in public sentiment is encouraging manufacturers to improve transparency and embrace circular practices.

In response to these forces, many companies are redesigning products with end-of-life in mind. Principles of "design for circularity" are gaining prominence: devices now use fewer distinct materials, incorporate recycled or bio-based components, and avoid permanently bonded assemblies. For example, Dell reports that it deliberately reduces the number of materials in each product and designs them so that "materials are more easily harvested for reuse and recycling." Similarly, firms are adopting modular architectures and standard screws to allow easy repair or recycling of parts. Such design changes aim to keep valuable materials in use longer and minimize waste.

Several companies have become leaders in sustainable design. Fairphone, a Dutch smartphone maker, is often cited as a pioneer of circular electronics. Its phones are built with easily replaceable modules (battery, screen, camera, etc.) so users can repair their own devices with simple tools. Fairphone also provides long software support and refurbishment: it reconditions returned phones and reuses recovered parts, effectively making each new sale "e-waste neutral." This model extends device lifetimes and dramatically reduces the volume of discarded electronics.

Even the biggest tech firms are stepping up. Apple, for instance, has developed advanced recycling robots (like "Daisy") to disassemble old iPhones into reusable parts. In 2024 Apple announced that Daisy can process 36 different iPhone models to recover critical materials. The company also reported that about 24% of the materials in its products came from recycled or renewable sources in 2024. By pairing such recycling innovations with design tweaks, Apple and others are working to shrink the environmental footprint of their electronics.

Industry-wide programs complement these efforts. Dell, for example, has recovered more than 2.5 billion pounds of used electronics since 2007, using plastics and metals from old devices to make new ones. Samsung similarly emphasizes circularity: it says all returned devices are "ethically recycled" and notes that it is incorporating recycled plastics and bio-based materials into many products. These initiatives show that recycling and reuse are becoming integral to tech business models. In combination, evolving regulations and growing consumer demand are moving the global electronics industry toward a more sustainable, circular future in which devices are designed, used and recycled with minimal waste.

We work how the property world works: sharp, collaborative, and on point. Every decision we make puts our customers first, solving problems, anticipating needs, and delivering unmatched service. We believe every property deserves to be presented with clarity and precision. We’re redefining floor plans as strategic assets, not just technical drawings. We combine precision, innovation, and brand integration to create floor plans that do more than outline space—they enhance marketing campaigns, elevate brands, and drive better property decisions.

As leaders in the industry, we have provided needed innovations to the industry including Gullwing Service Bodies, Rolaworx Drawers, and Uteworx Flat Decks. Our product range is continually growing with customer demand. Camco has the capacity and experience to supply specialist fitouts for many different industries. Time means money in business, and Camco’s systems are calculated to save time and create efficiencies.

It has been estimated that a Rolaworx drawer system could save 15 minutes per day. This adds up to over 62 hours a year over a 5 day week. Multiply that by your workers average hourly wage and see the savings! Camco understands the safety of vehicle operators are a top priority for businesses today. We design and develop our products around workplace safety, including safer access to tools, lighter fitouts, and crash tested solutions.

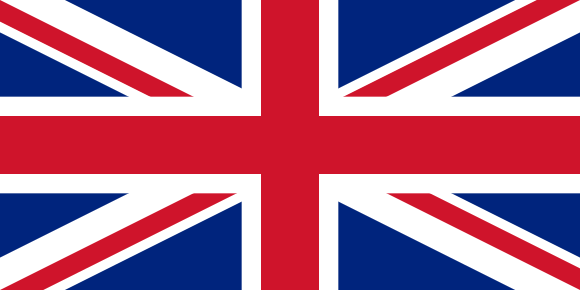

The Steptek Classic Colour BS Range from Redhill Manufacturing offers durable, mobile safety steps in various colours. Uniquely designed as the first mobile steps approved to the BS EN 131-7 standard for professional use. The Steptek Classic Colour Range are the UK's best-selling warehouse mobile steps. Offering robust, fully welded steel steps with a choice of 2 to 5 treads, vibrant colour options, and safety features like spring-loaded castors and handrails for optimal stability and versatility.

Every day we work hard to develop new digital transformation technologies that improve industrial and scientific operations. By focusing on building resilient high-performance systems, we strive to be our clients long-term technical innovation partner. We are grateful to work with many of you for over 25 years.

Since 1997 Sciotex has delivered the most innovative solutions to improve our client’s bottom line. Throughout our history, we’ve been fortunate to partner with the most respected manufacturing and scientific institutions in the world. From R&D to Proof of Concept to Full Deployment, Sciotex strives to minimize risk while pursuing high value returns through digital transformation. Contact us today to discuss your ideas.

We specialize in manufacturing animal feed machinery. Our products include hammer mills, mixers, granulators, extruders, dryers, pulverizers, coolers, coating machines, and automatic bagging machines. These products have been exported to Southeast Asia, Africa, South America, the Middle East, and other regions. We adopt integrated quality control throughout the manufacturing process and have earned ISO9001 international certification. All key electronic components are sourced from world-renowned brands to ensure the quality of our machines.

Our main products focus on pellet machines and supporting machinery, including animal feed pellet machines, chicken feed production lines, fish feed production lines, and pet food production lines. We are committed to becoming a professional partner who provides customers with technical solutions, design, installation, training, guidance, and other production management support to ensure seamless production. Future Fortune will be your one-stop feed machinery partner.

Inhabits the heart of the European publishing landscape, blending the elegance of French literary tradition with modern storytelling. The company has consistently championed a wide array of genres—ranging from scholarly works to mass-market titles—thereby positioning itself as a custodian of culture and innovation. Its editorial teams work intimately with authors to refine narratives while preserving the aesthetic and intellectual traditions that set French literature apart on the global stage.

Operationally, Hachette Livre intertwines sophisticated market analyses with an organic sense of literary passion. Its offices in Paris radiate creative energy, serving as hubs for professional development, international collaboration, and experimental digital formats. Constantly pushing boundaries, the publisher has embraced multimedia integrations and immersive storytelling experiences that cultivate a richer dialogue between creators and readers.

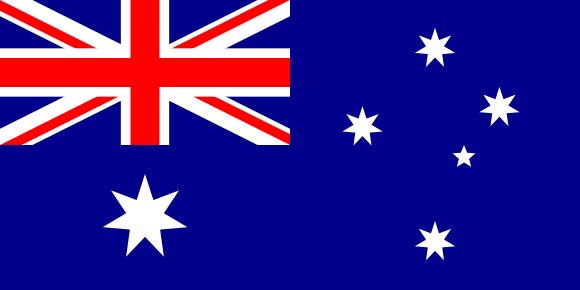

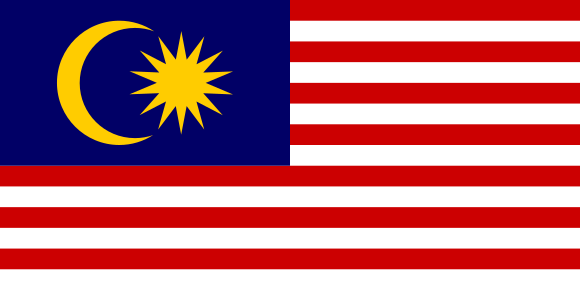

Blends traditional Malaysian batik techniques with contemporary design. Their flagship studio in Kuala Lumpur houses over 5,000 hand carved wooden blocks, each used to stamp intricate wax resist patterns onto textiles. Products range from scarves and dresses to upholstery fabrics sold wholesale to interior designers. The company employs artisans from rural Johor communities, providing stable incomes and apprenticeships in dyeing, drawing, and block carving.

Operations begin in their dye lab, where fabrics undergo multiple stages of waxing and dye baths using AZO free dyes. After patterning, textiles are boiled to remove wax and then sun dried on rooftop racks. Batik Boutique also runs corporate workshops and virtual masterclasses, teaching batik history and techniques to global audiences. Their showroom in Mont Kiara features rotating installations that showcase collaborations with fashion designers, emphasizing the versatility of batik in modern wardrobes.

Renowned for its transformative approach to professional services, seamlessly integrating strategy, consulting, digital, technology, and operations. The firm leverages its deep industry knowledge and cutting-edge technology solutions to help organizations harness agile methodologies and innovate for a digital-first future. By aligning business strategy with emerging technologies such as artificial intelligence, cloud computing, and advanced analytics, Accenture empowers clients to reimagine their core operations while building sustainable value in an ever-evolving market landscape.

In its global operations, Accenture is characterized by a vibrant culture of innovation and thought leadership. The company’s model is built on an extensive network of experts who not only drive market-leading digital transformations but also mentor clients on change management and operational agility. From reengineering legacy systems to pioneering cloud and data solutions, Accenture’s integrated approach ensures that every project is a tailored journey towards modernizing enterprises and unlocking competitive advantage.

We believe strongly that what we create, and the manner in which we create it, will filter down to the end user and help to improve the world we live in. We’re using the art of weaving in a contemporary manner to create quality products for people to treasure. Ethical trading and integrity underpins our philosophy, and we are particular about sourcing quality natural fibres.

Our fabrics are constructed to stand the test of time – we believe in creating textiles that are made to last and not destined for landfill. As a part of our sustainability, transparency and traceability objective, we hope that when people understand where something comes from and how it is made, they will value it more, and in turn this can help encourage conscious purchasing decisions.

Specializing in the production of high-quality rackets, and other sporting accessories, primarily for tennis and badminton. With a rigorous commitment to research and development rooted in Japanese precision, Yonex crafts equipment that elevates player performance through advanced design and innovative materials. Its products are the result of meticulous engineering, with every prototype undergoing extensive field testing to ensure that they deliver optimal balance and power distribution.

Beyond mere product excellence, Yonex has cultivated a vibrant global brand by aligning itself with internationally renowned athletes and tournaments. This strategic sponsorship and market positioning help to reinforce the quality and reliability of its equipment, while also inspiring the next generation of sports enthusiasts. By fusing cutting-edge innovation with traditional craftsmanship, Yonex continues to redefine performance standards in sports equipment and leisure, creating products that resonate in both professional circuits and local club gyms worldwide.